Video

Why Choose Us

Packing& Delivery

Product Description

| Product name | stainless steel Vertical check valve |

| Size | 1/4"-4" |

| Nominal pressure | PN16-40 |

| working temperate | -40℃-280℃ |

| Medium | water, oil, steam, gas,Nitric acid |

| materials | Stainless steel/WCB/CF8/CF8M |

| Connection | Flanged/threaded |

| Warranty | 1 year |

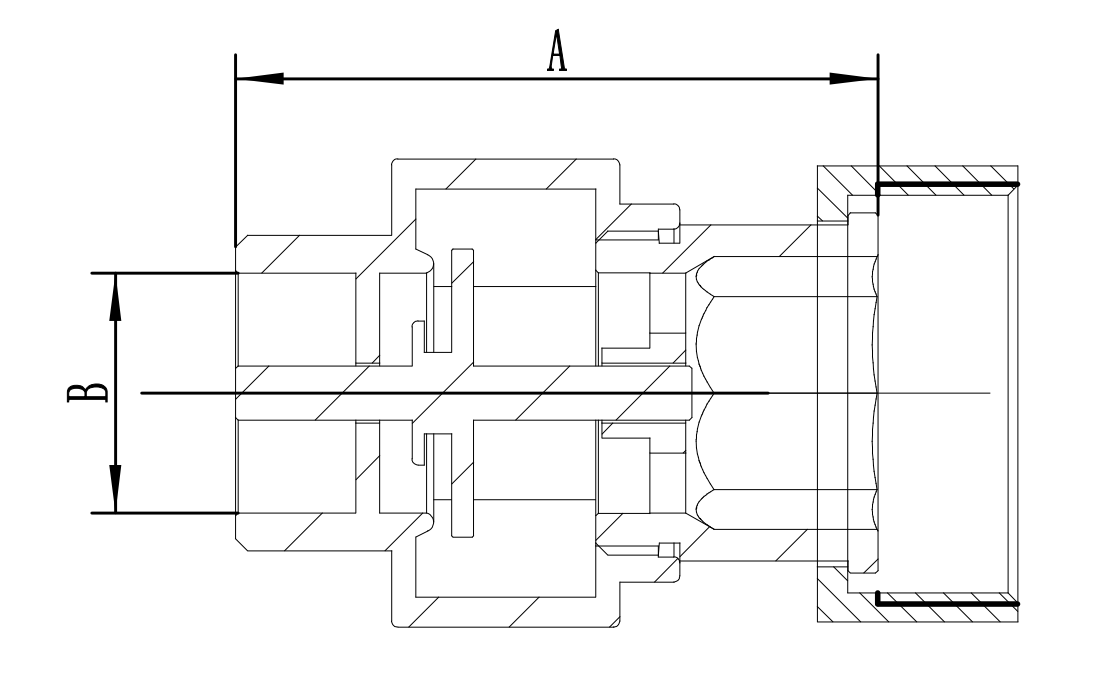

| SIZE | A | B |

| DN15 | 52 | 15 |

| DN20 | 53.5 | 20 |

| DM25 | 60.5 | 25 |

Specification

Specification 1.Working principle: The telescopic check valve is an automatic valve, which is mainly used in pipelines where the medium flows in one direction. It only allows the medium to flow in one direction and prevents the flow in the opposite direction. Under the action of the fluid pressure flowing in one direction, the valve flap opens , When the fluid flows in the opposite direction, it is closed by the self-weight of fluid pressure and spring force. At room temperature, when the pressure is 2-3bar and the flow rate is 1-2m/s, the pressure loss of DN15 horizontal check valve is about 800pa. , DN20 horizontal check valve pressure loss is about 500pa 2. Purpose and function: The telescopic check valve is mainly used in the HVAC system and the domestic water "water supply system". It automatically opens and closes by the force of the medium flow, and only allows the medium to flow in one direction to prevent The medium flows back. The check valve relies on the flow of the medium to automatically open and close the disc. The valve used to prevent the medium from flowing back is also called check valve, one-way valve, reverse flow valve and back pressure valve. Check valve is a kind of automatic valve. Telescopic check valves are often used to connect water meters to save space due to their small size. 3. Technical description: The valve body is made of high-quality stainless steel 304, which is resistant to pressure and corrosion, and uses high-precision finishing techniques during processing. 4.1. The telescopic check valve strictly implements the standards of GB/T 8464-2008 and GB/T 13927-2008 "Industrial Valve Pressure Test"; 4.2. The material is stainless steel 304; 4.3. Nominal pressure: 1.6Mpa; 4.4. Working medium: water, oil, gas; 4.5. Working temperature: -20℃≤t≤120℃; 4.6. The pipe thread complies with the ISO 228 standard. 5. Test conditions 5.1 The minimum working temperature is -20℃, the maximum working temperature is 120℃, the low temperature test requires -20℃, and the time is maintained for 60s without permanent damage. The high temperature test requires 120℃ and the time is maintained for 60s without permanent damage. ; 5.2 The size and thread conform to the test of caliper and thread gauge; 5.3 Sealing performance test: All products must pass the 0.6MPa air pressure 100%, and continue for 15s to test, and there is no leakage, which means they are qualified; 5.4 Torsion resistance performance: After the torque shown is applied to the valve for 10 seconds, there should be no damage or deformation, and meet the requirements of shell test and sealing performance;